Equipment and gauges

Functional equipment for production processes

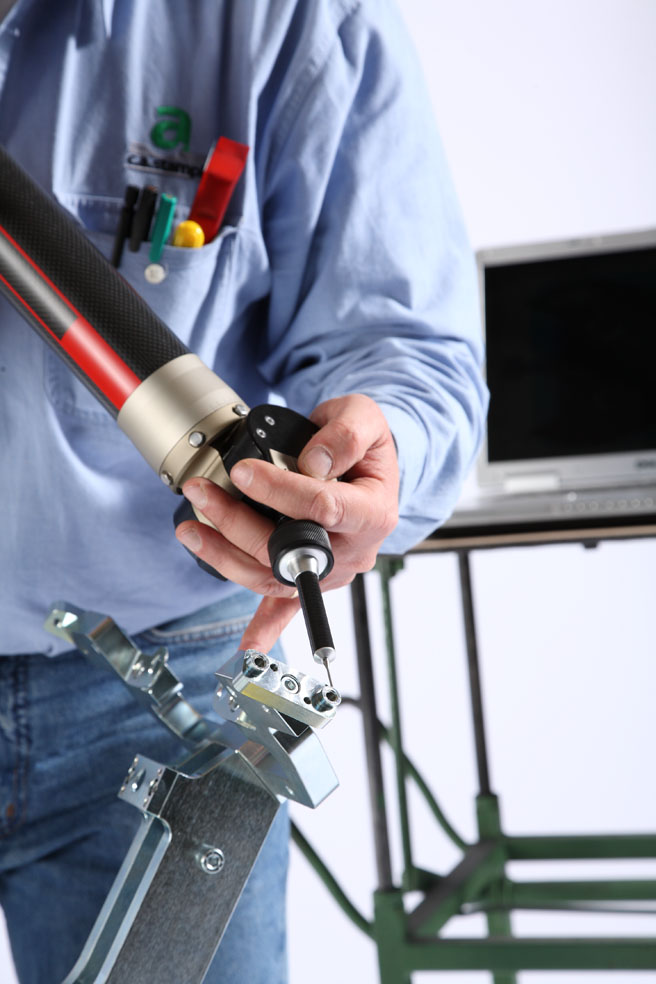

Our collaboration with the customer does not end with the design and construction of the moulds but then also covers the creation of all the necessary, production-supporting equipment, such as check masks, functional masks, locks, positioning components and other key parts needed to guarantee an efficient production process. Technological innovation and a team of professional technicians guarantee a quality result and a partnership that really works.

Control gauges for precision processes

We combine the tasks of constructing moulds and equipment with the creation of specific control gauges as well as functionality and test verification methods, on the line and throughout all production phases.

The use of a functional and precision control gauge increases production efficiency, while also ensuring compliance with technical requirements.

Characteristics of the Equipment and Gauges

- Equipment for mechanical machining in series production

- Positioning components for production lines

- Masks for assembling components

- Masks for shaping plastic components

- Semi-automatic pallets for machining on machining centres

- Design and construction of dedicated gauges

- Functional gauges for production lines

- Test gauges for product validation

- Dimensional certification for dedicated gauges